D i y multi usb hub – DIY Multi USB Hub: Tired of juggling multiple USB devices and running out of ports? Building your own multi-USB hub is easier than you think! This isn’t some rocket science project; we’re talking about empowering yourself with a surprisingly simple electronics project that saves you cash and gives you a serious bragging right. Get ready to dive into the world of soldering, circuits, and the ultimate satisfaction of creating something awesome from scratch.

From understanding the different types of USB hubs (powered vs. unpowered, data transfer speeds) to selecting the right components and mastering basic soldering techniques, this guide will walk you through each step. We’ll cover everything from circuit design and component selection to troubleshooting common issues and even designing a custom enclosure to match your style. Think of it as a crash course in electronics with a seriously useful end product.

Introduction to DIY Multi-USB Hubs

Building your own multi-USB hub might sound intimidating, but it’s a surprisingly rewarding project that offers several advantages over buying a pre-made one. You gain a deeper understanding of how USB technology works, customize it to your exact specifications, and often save money in the process. Plus, there’s a certain satisfaction in using something you created yourself!

DIY multi-USB hubs allow for greater control over functionality and design, letting you tailor the hub to your specific needs. For example, you can choose the number of ports, the type of power supply, and even the physical aesthetics of the device. This level of personalization simply isn’t possible with commercially available hubs.

Types of USB Hubs

USB hubs are categorized primarily by their power source and data transfer speeds. Unpowered hubs draw power directly from the computer’s USB port, limiting the number of devices they can support and potentially slowing down data transfer. Powered hubs, on the other hand, have their own power supply, enabling them to support more devices and offer faster data transfer rates. USB data transfer speeds vary depending on the USB version (USB 2.0, USB 3.0, USB 3.1, USB 4, etc.), with newer versions offering significantly faster speeds. Choosing the right type of hub depends entirely on your needs; if you need to power several devices or require high-speed data transfer, a powered hub with a suitable USB version is essential.

Essential Tools and Materials

Before you embark on your DIY multi-USB hub adventure, gather the necessary tools and materials. The specific components will vary depending on the complexity of your project, but a basic hub requires a handful of readily available items. A well-organized approach ensures a smoother building process.

| Tool | Quantity | Purpose | Alternative |

|---|---|---|---|

| Soldering Iron | 1 | To connect the components | Soldering gun (less precise) |

| Solder | 1 roll | To create electrical connections | (None – essential for soldering) |

| USB Hub PCB (Printed Circuit Board) | 1 | The base of the hub, containing the necessary circuitry | (None – the core of the project) |

| USB Cables (male to female) | Number of ports desired | To connect devices to the hub | (None – essential for functionality) |

| Power Supply (if using a powered hub) | 1 | To provide power to the hub | USB wall adapter with appropriate voltage and amperage |

| Wire Strippers/Cutters | 1 | To prepare the wires for soldering | Sharp knife (less safe and precise) |

| Multimeter | 1 | To test the connections and power supply | (Helpful, but not strictly necessary for a basic hub) |

| Helping Hands (optional) | 1 | To hold components while soldering | Small clamps or tape |

Circuit Design and Components

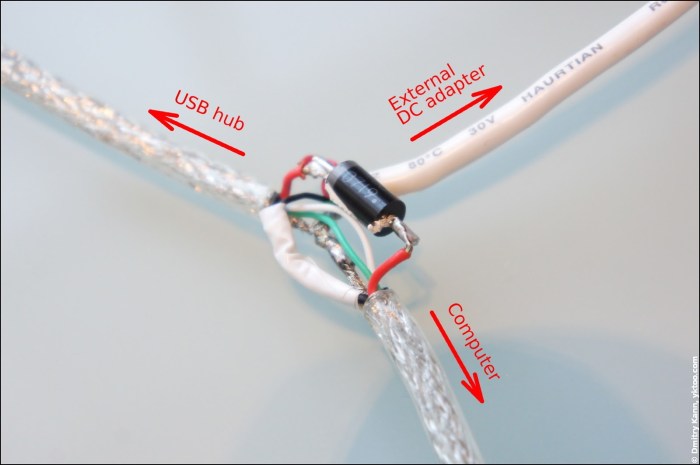

Building a multi-USB hub involves more than just plugging in connectors; it requires understanding the fundamental electrical flow and choosing the right components. A well-designed circuit ensures safe and efficient power distribution to your USB devices. This section breaks down the crucial aspects of designing your DIY multi-USB hub’s circuit.

Designing a simple circuit diagram for a multi-USB hub is surprisingly straightforward. At its core, it involves connecting multiple USB ports to a power source, managed through appropriate components to regulate voltage and current. The design centers around a power supply, which provides the necessary voltage and amperage, and a set of USB ports, acting as the output. Additional components, like resistors, are included to protect the circuit and devices from damage.

USB Connectors and Their Roles

The USB connectors are the interface between your hub and the devices you connect. Each connector requires specific wiring to handle data transmission and power delivery. The data lines (D+ and D-) carry the digital signals, while the power lines (VBUS and GND) supply power. Properly connecting these lines is crucial for functionality. Incorrect wiring can lead to device malfunction or even damage. Imagine connecting the data lines incorrectly – your computer might not recognize the device, or worse, it could damage the USB port.

Power Supply Options: Wall Adapter vs. Battery

Choosing the right power supply significantly impacts your hub’s functionality and portability. A wall adapter provides a consistent and readily available power source, offering higher power capacity. For instance, a 5V, 2A adapter would be sufficient for powering several USB devices simultaneously. However, it sacrifices portability. A battery, on the other hand, offers mobility, but limits the operational time and power output depending on the battery’s capacity. A typical lithium-ion battery pack might only sustain a few hours of operation at full load. The choice depends on your needs: a stationary hub might benefit from a wall adapter, while a portable one needs a battery.

Resistor Selection and Power Requirements, D i y multi usb hub

Resistors in a multi-USB hub primarily serve a protective role. They are not essential for basic functionality but are highly recommended for safety and reliability. They limit current flow to prevent overloads and protect connected devices from damage. Selecting appropriate resistors requires understanding power dissipation (P = I²R, where P is power in watts, I is current in amps, and R is resistance in ohms). For example, if a USB port draws 0.5A at 5V and we want a safety margin, we might use a 1Ω resistor. The power dissipated would be P = (0.5A)² * 1Ω = 0.25W. It’s crucial to choose a resistor with a power rating higher than the calculated value, say a 0.5W resistor, to ensure it doesn’t overheat and fail. This calculation applies to any resistor used in the current-limiting or protection circuit.

Soldering and Assembly Techniques: D I Y Multi Usb Hub

Building your own multi-USB hub is a rewarding experience, but the success hinges on your soldering skills. Proper soldering ensures a reliable and safe device. This section details the techniques and best practices to help you navigate this crucial step. We’ll cover soldering USB connectors and other components, focusing on safety and effectiveness.

Soldering USB Connectors

USB connectors are notoriously fiddly, with their small size and multiple pins. The key is patience and precision. Begin by preparing your workspace. Ensure good lighting and a clean, stable surface. Use a low-wattage soldering iron (25-30W is ideal for this type of work), ensuring the tip is clean and tinned (coated with a thin layer of solder). Position the connector firmly on the PCB, making sure the pins align perfectly with the pads. Apply a small amount of solder to each pin individually, using a steady hand and avoiding excessive heat. Too much heat can damage the connector or the PCB. A good solder joint should be shiny, smooth, and concave (like a tiny volcano), completely filling the space between the pin and the pad. Avoid bridging between pins, which can cause shorts. A magnifying glass can be invaluable for this detailed work.

Soldering Other Components

Soldering resistors, capacitors, and integrated circuits (ICs) requires similar precision, but the techniques may vary slightly depending on the component’s size and shape. For through-hole components (those that pass through the PCB), carefully align the component and solder each lead individually. For surface-mount components (SMD), which sit on the surface of the PCB, you’ll need a finer soldering iron tip and potentially a magnifying glass. Apply solder to the pads first, then place the component carefully. Use a minimal amount of solder to avoid shorts. The goal is a strong, secure connection.

Safe Soldering Practices

Safety is paramount when soldering. Always use a well-ventilated area to avoid inhaling fumes. Wear safety glasses to protect your eyes from solder splatters and hot metal. Avoid touching the soldering iron tip directly, as it can cause serious burns. Use a solder sucker or wick to remove excess solder if needed. Turn off the soldering iron when not in use and allow it to cool completely before storing it. Properly dispose of used solder and other materials according to local regulations.

Common Soldering Mistakes and How to Avoid Them

Several common mistakes can hinder your soldering success. Here are some of the most frequent errors and how to avoid them:

- Cold Solder Joints: These appear dull and lack a smooth, shiny surface. They indicate insufficient heat or improper solder application. Ensure adequate heat and proper solder flow.

- Solder Bridges: These occur when solder connects two adjacent pins unintentionally. Use a fine tip soldering iron and avoid excessive solder. A solder wick can help remove unwanted solder.

- Excess Solder: Too much solder can cause shorts and make the assembly look messy. Use only the necessary amount and clean up any excess with a solder wick or sucker.

- Insufficient Solder: Not enough solder leads to a weak connection and potential failure. Ensure the solder completely covers the connection.

- Burnt Components: Excessive heat can damage components. Use a low-wattage soldering iron and apply heat for only a short period.

Testing and Troubleshooting

So, you’ve soldered your way to a glorious multi-USB hub. Pat yourself on the back! But before you start charging all your gadgets simultaneously, let’s make sure this bad boy actually works. Testing your DIY creation is crucial, and knowing how to troubleshoot common problems will save you a heap of frustration. This section will walk you through the process, providing solutions and a handy flowchart to guide you.

Testing the functionality of your DIY multi-USB hub involves a systematic approach, checking both power delivery and data transfer capabilities. You’ll want to ensure each port functions correctly, delivering sufficient power and enabling seamless data communication. Remember, a faulty hub can lead to data corruption or even damage to your devices.

Power Supply Checks

Checking the power supply is the first step in troubleshooting. Insufficient power can manifest as devices not charging or intermittently disconnecting. Begin by verifying your power supply’s output voltage and amperage using a multimeter. Compare these readings to the specifications of your USB hub’s design. If the voltage is incorrect, check the power supply’s connections and wiring to your hub. A loose connection or a faulty wire could be the culprit. If the amperage is too low, consider using a higher-capacity power supply. For example, if your design requires 5V at 2A, but your supply only delivers 5V at 1A, you might experience problems with multiple high-power devices. Always double-check your wiring diagram to ensure everything is correctly connected.

Data Transfer Verification

After confirming adequate power, test the data transfer capabilities of each port. Connect a USB drive or other data storage device to each port and attempt to read and write data. Observe the transfer speeds – unusually slow speeds might indicate a problem with the data lines. If a specific port fails to transfer data, inspect the corresponding data lines on your hub’s circuit board for any visible damage or loose connections. Resoldering any suspect joints might resolve the issue. Remember to use a device that’s known to be functional to isolate the problem to the hub. If the problem persists, carefully re-examine your soldering work, paying particular attention to the data lines.

Short Circuit Detection

A short circuit is a serious problem that can damage your hub and connected devices. Symptoms include a blown fuse (if included in your design), overheating components, or the power supply shutting down. Use a multimeter to check for continuity between any two points that shouldn’t be connected. A low resistance reading indicates a short circuit. If a short circuit is detected, carefully inspect the circuit board for any bridging wires or solder bridges. A magnifying glass can help identify these tiny culprits. If you find a short, carefully remove the offending solder using a solder sucker or braid.

Troubleshooting Flowchart

This flowchart provides a visual guide to help you diagnose and resolve issues with your DIY multi-USB hub.

“`

[Start] –> [Check Power Supply (Voltage & Amperage)] –> [Correct? Yes/No]

No –> [Check Power Supply Connections & Wiring] –> [Problem Solved? Yes/No]

No –> [Use Higher Capacity Power Supply] –> [Problem Solved? Yes/No]

Yes –> [Test Data Transfer on Each Port] –> [All Ports Working? Yes/No]

No –> [Inspect Data Lines for Damage/Loose Connections] –> [Problem Solved? Yes/No]

No –> [Resolder Suspect Joints] –> [Problem Solved? Yes/No]

Yes –> [Check for Short Circuits (Multimeter)] –> [Short Circuit Detected? Yes/No]

No –> [End]

Yes –> [Inspect Circuit Board for Bridging Wires/Solder Bridges] –> [Problem Solved? Yes/No]

No –> [Remove Solder Bridge] –> [Problem Solved? Yes/No]

“`

Remember to always disconnect the power supply before making any adjustments to the circuit. Safety first!

Advanced Features and Modifications

Taking your DIY multi-USB hub from functional to fantastic involves exploring some exciting upgrades. These modifications not only enhance usability but also add a professional touch, showcasing your maker skills. Let’s delve into some advanced features you can incorporate.

Data Transfer Speed Indicators

Adding visual feedback in the form of LEDs can significantly improve the user experience. Each LED could represent a specific USB port, illuminating when data transfer is actively occurring. This requires careful circuit design. You’d need to tap into the data lines of each port, using a small circuit to detect data flow and trigger the corresponding LED. The brightness of the LED could even be proportional to the transfer speed, though this adds complexity. Consider using small, low-power LEDs to minimize power consumption and maintain a sleek design. For instance, a tiny blue LED next to each port could subtly pulse when data is being transferred, providing a clear visual cue without being distracting.

Over-Current Protection

Protecting your devices and your hub from power surges is crucial. Over-current protection prevents damage from short circuits or overloads. A simple and effective solution is to incorporate a PolySwitch resettable fuse into the power supply line. This device automatically cuts the power if the current exceeds a predetermined threshold, protecting the connected devices and the hub itself. The PolySwitch will reset once the overload condition is removed, restoring power to the hub. Choosing the appropriate PolySwitch rating is essential, considering the maximum current draw of the USB ports and any additional components. For example, a 2A PolySwitch would be suitable for a hub designed to power several low-power devices.

Power Switch Integration

Adding a power switch offers convenient control over the hub. A simple on/off switch can be incorporated into the circuit, placed strategically within the enclosure for easy access. Consider using a miniature slide switch or a tactile push-button switch, depending on your aesthetic preferences and the overall size of your hub. The switch should be wired in series with the power supply line, effectively breaking the circuit when switched off. Properly integrating the switch into the design requires careful planning to ensure easy access and a clean look.

Aesthetically Pleasing Enclosure Design

The enclosure significantly impacts the overall look and feel of your DIY hub. While functionality is paramount, a well-designed enclosure elevates the project. Consider using materials like laser-cut acrylic for a modern, transparent look, or 3D-printed PLA for a more customizable design. The enclosure should be robust enough to protect the internal components while allowing for easy access to ports and switches. Thoughtful cable management within the enclosure contributes to a cleaner, more professional appearance. A well-designed enclosure can transform your functional hub into a stylish accessory. Imagine a sleek, black acrylic box with neatly arranged ports and a subtle power switch – a far cry from a jumble of wires and components.

Safety Considerations

Building your own multi-USB hub is a rewarding project, but it’s crucial to prioritize safety throughout the process. Working with electronics and soldering involves potential hazards if proper precautions aren’t taken. This section Artikels essential safety measures to ensure a safe and successful build.

Proper grounding and insulation are paramount to prevent electrical shocks and short circuits. Incorrect wiring or component selection can lead to malfunctions, damage to your components, or even fire. Adhering to safety regulations minimizes risks and protects you from harm.

Electrical Hazards

Working with electricity always carries inherent risks. Even low voltages can cause unpleasant shocks, and higher voltages pose a significant danger. Always ensure your workspace is well-lit and free from clutter to prevent accidental contact with exposed wires or components. Never work on electronics when you are tired or distracted, as this increases the likelihood of mistakes. Before beginning any soldering or wiring, unplug the power supply from the wall outlet. When working with higher voltages, use appropriate safety equipment, such as insulated tools and gloves.

Soldering Safety

Soldering involves working with hot metal and potentially hazardous fumes. Always use a well-ventilated area to avoid inhaling fumes. Ensure your soldering iron is properly grounded to prevent electrical shocks. Use a soldering iron stand to prevent accidental burns and fires. Never leave a hot soldering iron unattended. Wear safety glasses to protect your eyes from solder splatter. Keep a damp sponge or cloth nearby to clean the soldering iron tip and remove excess solder.

Component Handling

Electronic components are delicate and can be easily damaged by static electricity. Use an anti-static wrist strap connected to a grounded surface to prevent static discharge. Handle components carefully to avoid bending pins or breaking leads. Always double-check your wiring diagram before connecting components to ensure correct polarity and avoid short circuits. Improper handling can lead to malfunctioning devices or even irreversible damage.

Safety Regulations

Before starting your project, familiarize yourself with relevant safety regulations and guidelines for working with electronics and soldering equipment. These regulations vary depending on your location, but common practices include using appropriate personal protective equipment (PPE), such as safety glasses and gloves; ensuring proper ventilation; and following manufacturer instructions for all tools and components. Consult local and national safety standards for electronics assembly and repair for detailed guidelines. Ignoring these regulations can lead to injury or damage.

Case Design and Construction

Building a sturdy and aesthetically pleasing case for your DIY multi-USB hub is the final, crucial step in the project. A well-designed case protects your circuitry, enhances its look, and makes it easier to use. Choosing the right materials and construction method will ensure your hub is both functional and visually appealing.

The choice of enclosure material significantly impacts the final product’s look, feel, and durability. Several options exist, each with its own set of advantages and disadvantages.

Material Selection for the Enclosure

Selecting the right material depends on factors like your desired aesthetic, the level of protection required, and your budget. Here’s a comparison of popular options:

Plastic offers a lightweight, inexpensive, and readily available solution. Acrylic or ABS plastics are good choices due to their durability and ease of machining. They can be easily cut and shaped using tools like a laser cutter or a Dremel. However, plastics can be prone to scratches and might not offer the same level of robustness as metal. A simple rectangular box made from a thick piece of acrylic would be both elegant and protective.

Metal enclosures, such as those made from aluminum, offer superior durability and shielding against electromagnetic interference (EMI). Aluminum is relatively easy to work with and can be purchased in various thicknesses and finishes. However, metal enclosures are generally more expensive and require more specialized tools for cutting and shaping. A brushed aluminum case would give a premium feel and excellent shielding.

Wood, particularly hardwoods like walnut or maple, provides a unique and visually appealing option. Wood offers a warm, natural aesthetic and can be finished to a high level of polish. However, working with wood requires more skill and specialized tools. You’ll need to ensure the wood is properly sealed to protect the electronics from moisture. A small, neatly crafted wooden box would be a unique and attractive solution.

Creating Custom Cutouts

Precise cutouts are essential for accessing the USB ports and other components. The method you choose will depend on the enclosure material and your available tools.

For plastic and wood enclosures, a laser cutter offers the most precise and efficient method for creating cutouts. It allows for intricate designs and clean edges. Alternatively, a Dremel tool with various bits can be used for less intricate designs. Careful measurements and a steady hand are crucial to avoid damaging the material.

For metal enclosures, a CNC milling machine provides the most precise results. However, this requires access to specialized equipment. Alternatively, a drill press and various drill bits can be used to create holes for the USB ports and other components. A file can then be used to refine the edges.

Enclosure Assembly and Component Securing

Once the cutouts are complete, it’s time to assemble the enclosure and secure the internal components.

For plastic and wood enclosures, adhesive such as strong epoxy or specialized plastic adhesives can be used to bond the enclosure pieces together. The internal components can be secured using screws, double-sided tape, or hot glue, depending on their size and weight. Ensure that the USB ports are firmly mounted and aligned correctly.

For metal enclosures, screws and nuts are typically used to fasten the enclosure pieces together. The internal components can also be secured using screws or standoffs to prevent short circuits. Proper grounding is essential for metal enclosures to prevent EMI issues.

Regardless of the material, consider adding rubber feet to the bottom of the enclosure to prevent slipping and to protect the surface it rests on. A well-thought-out assembly process ensures a robust and aesthetically pleasing final product.

Closure

So, there you have it – your very own DIY multi-USB hub! From a simple circuit diagram to a fully functional device, you’ve conquered the world of basic electronics. Not only have you saved money by avoiding a pricey store-bought hub, but you’ve also gained a valuable skill and a sense of accomplishment. Now go forth, and impress your friends with your newly acquired tech wizardry. And who knows, maybe this is the start of your next great maker project!

Big Data Solution Big Data Solution

Big Data Solution Big Data Solution